In the pursuit of more sustainable practices, businesses across various industries are increasingly seeking eco-friendly alternatives to traditional packaging and product manufacturing. One such solution is the use of pulp mold, a biodegradable material made from recycled paper, cardboard, and other fibrous materials. Pulp molding offers a range of environmental and operational benefits, from reducing plastic waste to lowering carbon footprints. This article will explore how to incorporate pulp mold into your business for eco-friendly solutions.

Understanding Pulp Mold and Its Benefits

Pulp mold is a sustainable material that is created by molding recycled paper fibers mixed with water. The resulting product is versatile, biodegradable, and can be used for a variety of applications. Pulp molding has been widely adopted in packaging, protective containers, and even as components in the automotive and electronics industries. The environmental benefits of using pulp mold are significant. Not only does it reduce reliance on plastic, but it also supports recycling efforts by utilizing paper waste that would otherwise end up in landfills.

In addition to being eco-friendly, pulp mold is a cost-effective alternative to traditional packaging and products. It offers excellent shock absorption, which makes it ideal for packaging fragile items. Unlike plastic, pulp mold can be composted or recycled at the end of its life cycle, contributing to a circular economy. As businesses look for ways to enhance their sustainability credentials, incorporating pulp mold into their operations presents a valuable opportunity to reduce waste and promote environmentally responsible practices.

Incorporating Pulp Mold in Packaging Solutions

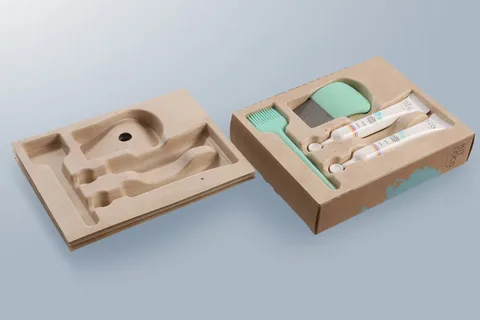

One of the most popular uses for pulp mold is in the creation of eco-friendly packaging solutions. Pulp molding can replace plastic and Styrofoam packaging, which are notorious for their environmental impact. Businesses that use pulp mold for packaging can significantly reduce their carbon footprint and showcase their commitment to sustainability. Pulp mold can be molded into various shapes and sizes, making it suitable for packaging a wide range of products, from electronics and cosmetics to food and beverages.

To successfully incorporate pulp mold into packaging solutions, businesses should start by identifying their packaging needs. Are they shipping fragile products that require cushioning? Are they looking for sustainable packaging for their retail products? By understanding their requirements, businesses can work with pulp molding manufacturers to develop customized solutions. Additionally, businesses should consider integrating branded pulp mold packaging, which not only enhances the aesthetic appeal of products but also reinforces the brand’s eco-conscious message.

How Pulp Mold Can Be Used for Product Manufacturing

Beyond packaging, pulp mold can be utilized in the manufacturing of products. Items such as trays, containers, and even furniture components can be made using pulp mold. This offers manufacturers the chance to create sustainable products that meet the growing consumer demand for eco-friendly solutions. For instance, businesses in the foodservice industry can use pulp mold for takeout containers and cutlery, which are compostable and biodegradable. Similarly, industries that require protective components, such as automotive and electronics, can benefit from the shock-absorbing qualities of pulp mold.

Incorporating pulp mold into product manufacturing also helps reduce material costs. Since pulp mold is made from recycled paper and other fibers, it can be sourced at a lower cost than many conventional materials. Additionally, the ability to mold pulp into complex shapes means that it can replace materials that require additional processing, such as plastics or metals. By exploring the potential of pulp mold, businesses can diversify their product offerings while simultaneously reducing their environmental impact.

Overcoming Challenges in Implementing Pulp Mold Solutions

While the benefits of using pulp mold are clear, there are also challenges that businesses may face when adopting this material. One of the main hurdles is the initial cost of transitioning from traditional materials to pulp mold. Although pulp mold is often cheaper than plastic in the long run, the investment required for new molding equipment and sourcing sustainable raw materials can be daunting for some businesses. Additionally, businesses must ensure that they are working with reliable suppliers who provide high-quality pulp mold products that meet regulatory standards.

Another challenge lies in educating customers and stakeholders about the advantages of pulp mold. While awareness of environmental issues is growing, some businesses may still face resistance from customers who are unfamiliar with this alternative. To overcome this, businesses should invest in marketing campaigns that highlight the eco-friendly benefits of pulp mold, such as its biodegradability and recyclability. By creating clear messaging and showcasing the advantages of pulp mold, businesses can build consumer trust and increase the adoption of this sustainable solution.

The Future of Pulp Mold in Sustainable Business Practices

The future of pulp mold looks promising, as businesses and consumers continue to prioritize sustainability in their choices. With governments around the world introducing stricter regulations on plastic use, the demand for alternatives like pulp mold is expected to rise. The versatility of pulp mold, combined with its eco-friendly properties, positions it as a key player in the transition to more sustainable business practices. Companies that incorporate pulp mold into their operations now will not only reduce their environmental footprint but also position themselves as leaders in the growing green economy.

Looking ahead, innovations in pulp molding technology are likely to further enhance the material’s potential. Researchers are exploring ways to improve the durability and water resistance of pulp mold, which could open up new applications in sectors such as construction and agriculture. As the material continues to evolve, businesses that embrace pulp mold today will be well-positioned to take advantage of future developments, ensuring their sustainability initiatives remain at the forefront of their industries.

Conclusion

Incorporating pulp mold into your business for eco-friendly solutions is a step toward a more sustainable future. By replacing plastic packaging, manufacturing eco-friendly products, and exploring new applications, businesses can not only reduce their environmental impact but also enhance their brand’s reputation as a forward-thinking, environmentally conscious organization. Despite some initial challenges, the long-term benefits of pulp mold—ranging from cost savings to improved sustainability—make it a valuable addition to any business’s operations. With continued innovation and growing consumer demand for sustainable solutions, pulp mold is poised to play a significant role in shaping the future of green business practices.