The aerospace industry demands exceptional precision, durability, and performance from its components. To meet these stringent requirements, manufacturers increasingly rely on Aerospace CNC Machining, a process that combines advanced computer-controlled tools with high-performance materials. In this article, we explore the significant advantages of Aerospace CNC Machining and why it has become indispensable in crafting high-performance aerospace components.

Superior Precision for Critical Components

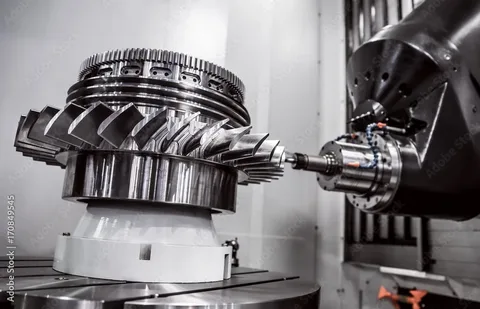

Aerospace CNC Machining provides unparalleled precision, an essential quality for aerospace components that must operate under extreme conditions. This machining process relies on computer-aided design (CAD) and computer-aided manufacturing (CAM) software to execute intricate designs with minimal margins of error. The advanced programming ensures that every cut, hole, and groove meets the exact specifications required for performance and safety.

For critical components like turbine blades, landing gear, and engine parts, even the smallest deviation can lead to catastrophic failures. CNC machining eliminates these risks by offering repeatable accuracy, ensuring every component functions perfectly. This level of precision not only improves reliability but also extends the lifecycle of aerospace parts, reducing downtime and maintenance costs.

Enhanced Material Versatility

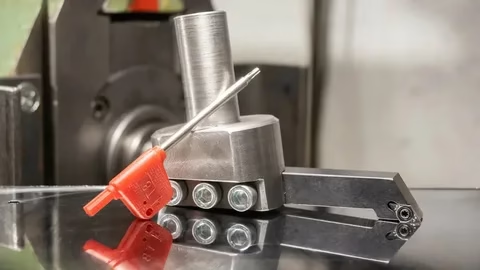

The aerospace sector utilizes a variety of high-performance materials, including titanium, aluminum, and superalloys, to create components that can withstand intense heat, pressure, and wear. Aerospace CNC Machining is equipped to handle these materials effectively, offering flexibility that traditional machining techniques cannot match.

By employing specialized cutting tools and advanced cooling systems, CNC machining can shape these durable materials without compromising their structural integrity. This versatility enables manufacturers to design components that meet the unique demands of aerospace applications, such as lightweight structures with exceptional strength. Moreover, CNC machining’s adaptability reduces material waste, leading to more efficient production cycles.

Increased Production Efficiency

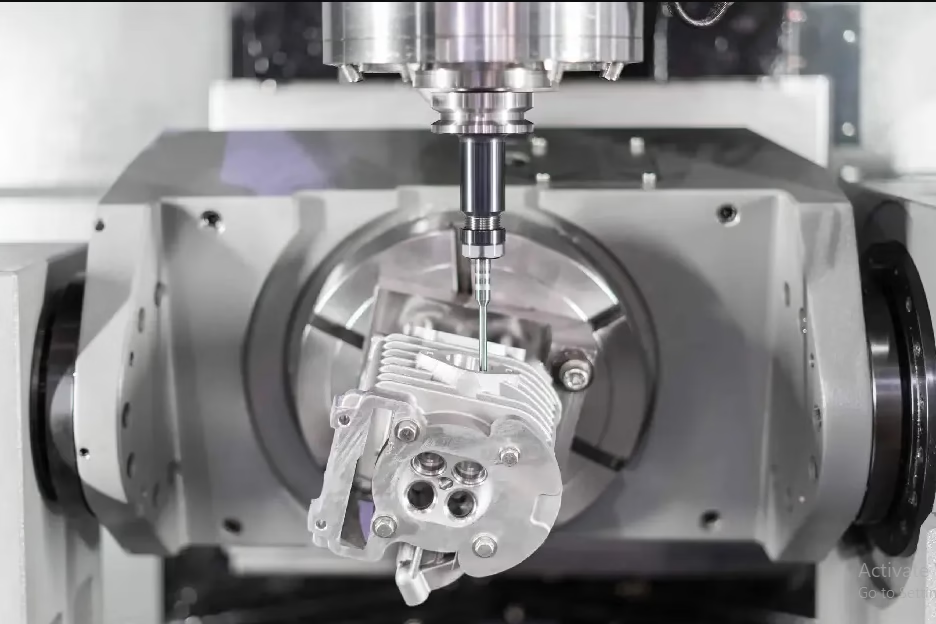

Time is a critical factor in aerospace manufacturing, where delays can lead to significant financial losses. Aerospace CNC Machining excels in optimizing production efficiency through automation and speed. The integration of high-speed tools, multi-axis capabilities, and real-time monitoring systems enables faster turnaround times without sacrificing quality.

The automation inherent in CNC machining reduces human error and minimizes the need for manual intervention, streamlining the production process. Manufacturers can also program CNC machines to handle multiple components simultaneously, increasing output. This efficiency allows aerospace companies to meet tight deadlines and adapt to rapidly changing industry demands.

Improved Quality Control and Consistency

Consistency is vital in the aerospace industry, where every component must meet rigorous quality standards. Aerospace CNC Machining ensures uniformity across production batches by following programmed instructions with extreme precision. This eliminates inconsistencies often associated with manual machining processes.

Additionally, CNC machines integrate advanced quality control measures, such as in-process inspections and real-time feedback systems, to detect and correct errors during production. These features ensure that each component adheres to aerospace certification requirements, enhancing overall product quality and reducing the risk of failures in service.

Cost-Effectiveness Over the Long Term

Although the initial investment in Aerospace CNC Machining technology may be high, the long-term benefits outweigh the costs. The process reduces material waste, lowers labor expenses, and minimizes costly errors, all of which contribute to significant savings over time.

Furthermore, the durability and reliability of CNC-machined components reduce maintenance and replacement costs. By delivering parts that perform better and last longer, Aerospace CNC Machining enables manufacturers to achieve higher returns on investment. This cost-effectiveness is especially crucial for aerospace projects, where budget optimization is as important as performance.

Conclusion

Aerospace CNC Machining has revolutionized the manufacturing of high-performance components by offering unmatched precision, material versatility, production efficiency, quality control, and cost-effectiveness. Its advanced capabilities make it the backbone of modern aerospace engineering, ensuring that components meet the industry’s demanding standards for safety and performance. As aerospace technology continues to evolve, CNC machining will remain an essential tool in crafting the next generation of innovative and reliable components.