Introduction

The evolution of CNC (Computer Numerical Control) technology has fundamentally transformed the manufacturing industry, enabling faster production, greater precision, and enhanced capabilities. Among the various advancements in CNC machining, 5-axis machining stands out as a game-changer, offering unparalleled accuracy and versatility for complex part production. This article explores the concept of 5-axis CNC machining, how it works, its benefits, applications, and the industries that rely on this cutting-edge technology.

What is 5-Axis CNC Machining?

CNC machining refers to the use of computer-controlled machines to perform a wide range of operations, such as milling, turning, drilling, and grinding. Traditional CNC machines typically work along three linear axes (X, Y, and Z), meaning they can move in three directions: left-right, forward-backward, and up-down. These machines can perform a variety of tasks but are limited when it comes to machining more complex or intricate parts.

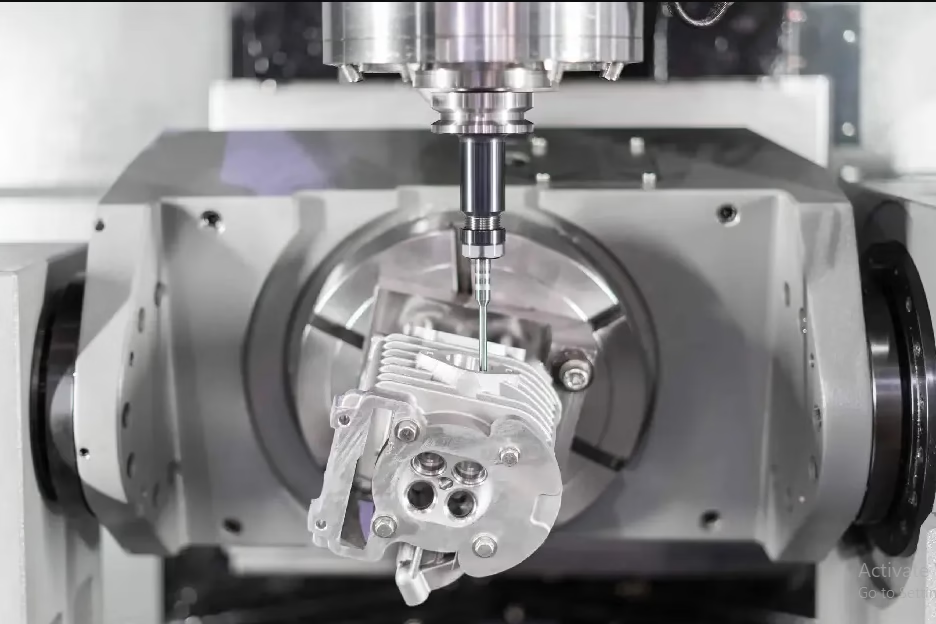

5-axis CNC machining takes this technology a step further by adding two additional rotational axes. In a 5-axis system, the machine can simultaneously move along the X, Y, and Z linear axes while also rotating the part on two additional axes, typically referred to as A and B axes. This allows for the creation of highly intricate and detailed parts with fewer setups and greater precision.

There are two main configurations of 5-axis machines:

- Rotary Table Machines: The workpiece rotates on the A and B axes while the cutting tool moves along the X, Y, and Z axes.

- Head-Table Machines: The cutting tool rotates along the A and B axes while the workpiece moves along the X, Y, and Z axes.

How Does 5-Axis CNC Machining Work?

The key advantage of 5-axis machining lies in its ability to approach the workpiece from virtually any direction, eliminating the need for multiple setups. Traditional 3-axis machines often require repositioning the part several times during the machining process to reach all areas, which can lead to errors, misalignment, and inefficiency. With 5-axis CNC machines, both the part and the tool can be manipulated simultaneously in multiple directions, reducing setup time, improving accuracy, and minimizing the risk of errors.

The process involves the following steps:

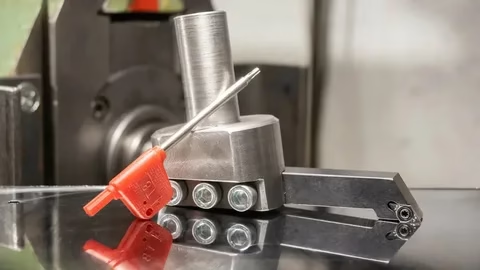

- Programming: Using CAD (Computer-Aided Design) software, the design of the part is created or imported. The software generates the necessary toolpaths for the CNC machine, taking into account the specific material, tool, and cutting conditions.

- Setup: The part is securely mounted on the machine’s worktable. In 5-axis machines, the part is often mounted on a rotary table or fixed to a fixture that allows for movement along multiple axes.

- Machining: The machine begins the machining process, where it simultaneously moves the part and the cutting tool along the X, Y, Z, A, and B axes. This enables the tool to access difficult angles and contours without requiring additional setups.

- Finishing: After the roughing process, the machine can perform finishing passes with a high level of precision to achieve the final shape and surface finish.

The ability to approach the workpiece from multiple angles at once allows for intricate geometries, sharp corners, and deep cavities that would be difficult, if not impossible, to achieve with traditional methods.

Advantages of 5-Axis CNC Machining

The adoption of 5-axis CNC machining has brought about numerous benefits for industries that require precision and complex part production. Here are some of the most significant advantages:

1. Enhanced Precision and Accuracy

5-axis CNC machining enables the production of highly accurate parts with extremely tight tolerances. The ability to move both the workpiece and the cutting tool simultaneously minimizes errors caused by repositioning, resulting in parts that are more consistent and precise.

2. Reduced Setup Time

With traditional CNC machines, multiple setups are required to access different sides of a part. However, with 5-axis machines, the need for repositioning is eliminated, as the machine can access all sides of the part in a single setup. This results in significant time savings, which can increase overall productivity.

3. Improved Surface Finish

5-axis CNC machining can achieve smoother surface finishes with greater precision, making it ideal for applications where surface quality is critical. The machine can approach the material from multiple angles, allowing for better control over the cutting process and reducing the risk of tool marks and imperfections.

4. Ability to Machine Complex Geometries

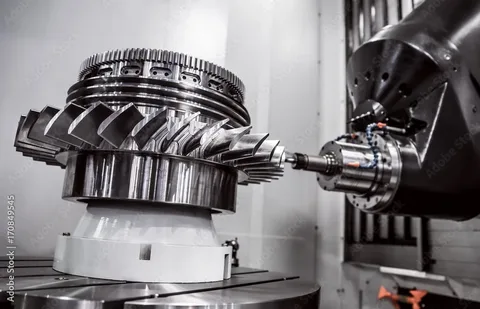

5-axis CNC machines can create parts with complex shapes and intricate geometries that would be challenging or impossible to produce with traditional 3-axis machines. This capability is essential for industries like aerospace, medical devices, and automotive, where highly detailed and customized parts are required.

5. Increased Tool Life

The advanced control of 5-axis machining ensures that tools are used more efficiently. Since the cutting tool can approach the material from optimal angles, there is less stress on the tool, leading to longer tool life. This, in turn, reduces downtime and the cost of tool replacements.

6. Higher Material Removal Rates

With the ability to approach the part from multiple angles and the increased cutting efficiency, 5-axis machines can remove material faster, improving overall machining times. This makes it easier to produce large volumes of parts in a shorter period.

Applications of 5-Axis CNC Machining

5-axis CNC machining has become indispensable in many high-precision industries. Here are some of the key sectors that benefit from this technology:

1. Aerospace Industry

The aerospace industry demands parts that are both lightweight and highly precise. 5-axis CNC machining allows manufacturers to produce complex components like turbine blades, engine parts, and structural components with intricate geometries and tight tolerances. The ability to machine parts in a single setup also reduces the risk of errors and misalignment, which is crucial in the aerospace sector.

2. Medical Device Manufacturing

Medical devices, including surgical instruments, implants, and prosthetics, require precise manufacturing with complex shapes. 5-axis machining allows for the production of these parts with the necessary accuracy, while also ensuring smooth surface finishes to meet the stringent standards of the medical industry.

3. Automotive Industry

In the automotive sector, 5-axis CNC machining is used to manufacture components like engine blocks, transmission parts, and complex moldings. The technology’s ability to produce precise and complex parts at a high rate of speed is essential in meeting the demands of automotive manufacturing.

4. Tool and Die Making

Tool and die manufacturers often rely on 5-axis CNC machines to produce molds and dies for injection molding, casting, and stamping. The ability to create complex shapes with tight tolerances makes 5-axis machining ideal for this application.

5. Prototyping and Custom Manufacturing

5-axis CNC machining is also widely used in prototyping and custom manufacturing, where one-of-a-kind parts or low-volume production runs are required. The versatility of 5-axis machines makes it easy to produce highly detailed prototypes and customized parts quickly and efficiently.

Industries Benefiting from 5-Axis CNC Machining

While aerospace, automotive, medical, and toolmaking industries are the primary users of 5-axis CNC technology, it is also utilized in other sectors, including:

- Defense

- Oil and gas

- Energy

- Electronics

- Consumer products

The ability to produce highly complex parts with high accuracy has made 5-axis CNC machining an invaluable tool across these diverse industries.

Conclusion

5-axis CNC machining is a transformative technology that has revolutionized manufacturing, allowing for the production of parts with greater precision, efficiency, and complexity than ever before. Its ability to reduce setup time, improve surface finishes, and machine intricate geometries has made it an essential tool for industries that demand high-quality, complex parts. Whether in aerospace, automotive, medical devices, or other sectors, 5-axis CNC machining continues to drive innovation and efficiency in the world of modern manufacturing. As technology continues to evolve, the capabilities and applications of 5-axis machining are only expected to expand, further cementing its importance in the global manufacturing landscape.